Deborah J. Cooper

FAIA, LEED AP

Principal

Happy Earth Day from the 2030 Committee at Architectural Resources Group! To celebrate this year, we are sharing some of the firm’s sustainability initiatives under research and development over the past few months. As the firm’s “green team,” we look forward to continuing our mission to help meet the AIA’s 2030 Commitment, help ARG’s work reach net zero carbon, and make our practice as sustainable as possible.

We currently study several new tools and technologies to help us better understand the environmental impacts of our design. By running simulations and tests through internal pilot programs, we developed strategies to integrate two new tools, CARE Tool and cove.tool, into the firm’s standard design processes and workflow.

CARE Tool – Projecting Carbon Impact

With a motto of “We can’t build our way to net zero,” CARE Tool is a great place to start for projects that utilize existing structures. Short for Carbon Avoided: Retrofit Estimator, CARE Tool allows us to compare the total carbon emissions of a project proposal using preliminary project data. CARE Tool generates three project alternatives (do nothing, upgrade or add to the existing structure, or demolish and rebuild) and estimates their two major carbon categories: embodied and operational.

Embodied carbon is often ignored as it is not visible once the building is inhabited by users. The emissions from manufacturing, transporting, installing, and the ultimate disposal of products all count towards a building’s embodied carbon. When a building element is being reused, the embodied carbon is zero because it’s already on site, it’s already installed, and the greenhouse gases have already been emitted. On the other hand, operational carbon is the more visible type of carbon emission. Think lighting, heating & cooling, ongoing maintenance, and ventilation. The AEC industry often focuses on minimizing the operational carbon of projects, but embodied and operational carbon have the same impact on the environment.

CARE Tool brings awareness to this difference by estimating the initial embodied carbon of the three schemes and estimates the accumulated operational carbon emitted over a project’s lifespan. Because of the large amount of embodied carbon that goes into the construction of a new, more energy-efficient building, it may take upwards of 10 or 15 years for the total carbon emissions of the new construction to amount to less than the combined operational carbon of the existing project. ARG is using CARE Tool to optimize the percentage of selective demolition and upgrades to a project – an alternative that honors our commitment to preservation while allowing our projects to look towards the future.

For our ongoing work with the Pasadena Conservatory of Music, our CARE Tool calculations were made over the course of a 15-year simulation. Results from the tool are displayed graphically as a bar chart displaying embodied vs. operational emissions as a sum over 15 years, as well as a line graph of combined emissions over time.

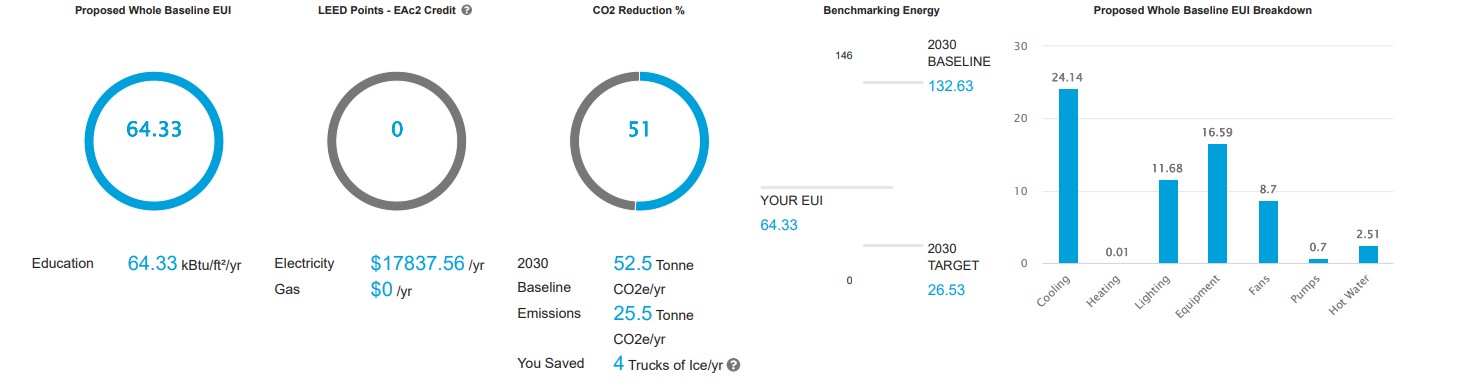

Cove.tool – Insightful Energy Modeling

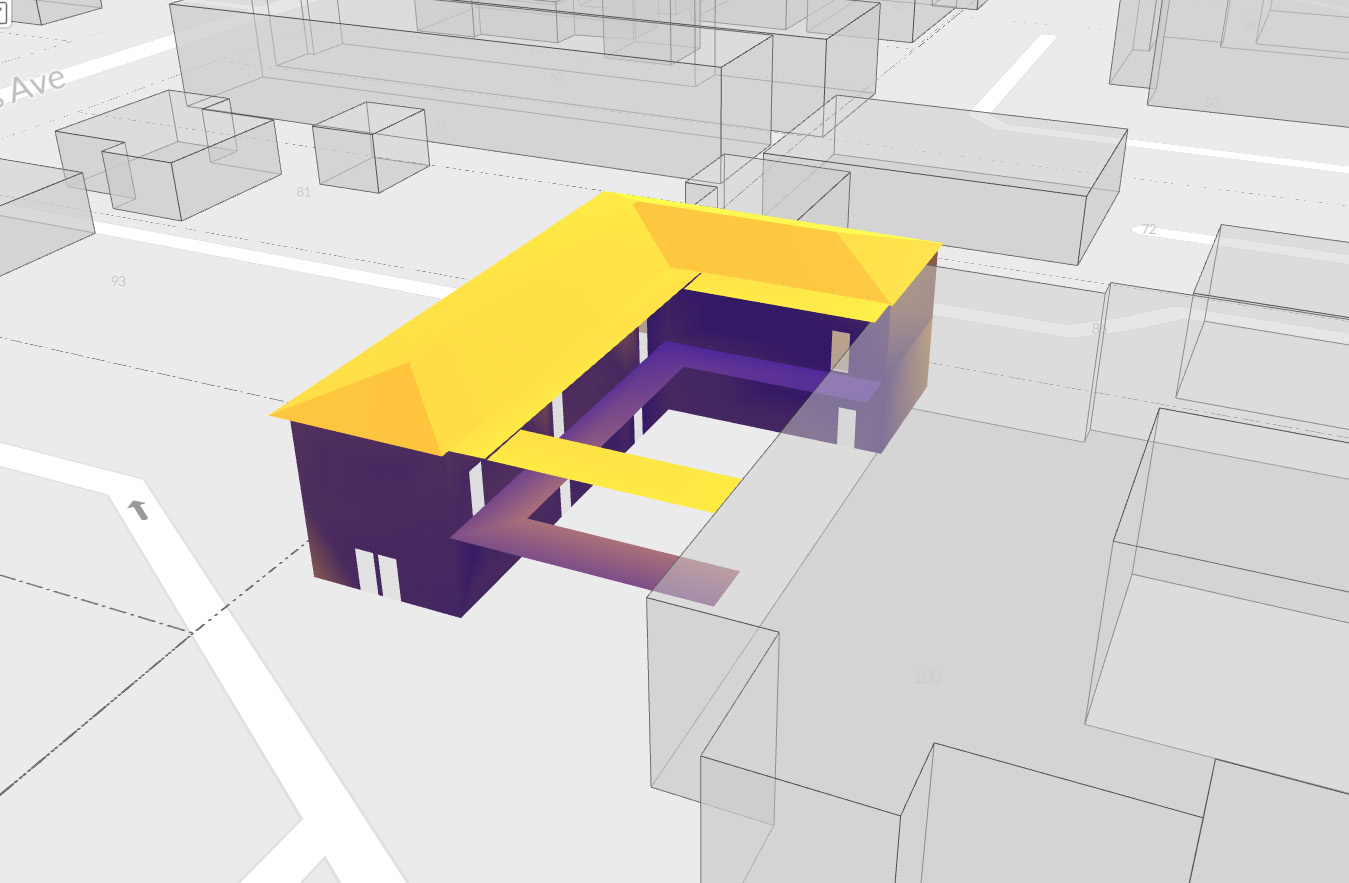

Once a project direction has been selected through CARE Tool, our project team utilizes Cove.tool to run results-based 3D geometry. Our Revit, Sketchup, and Rhino models can be uploaded to Cove.tool’s website and placed on the project site to simulate the effects of climate, daylight hours, and urban context on the geometry. Additional information such as the R-value of wall & roof assemblies and HVAC system types can then be input into the tool to estimate the project embodied carbon and the energy use intensity, or EUI. The EUI of a building represents the building’s total yearly energy consumption over the gross square footage. The lower the EUI, the better the building performs and emits less operational carbon.

ARG uses Cove.tool throughout the design process. In programming and schematic phases, models consisting of just walls and a roof can be used to test out the best location, orientation, and form on the site. During later phases of design, more specific values such as U and R values of glazing can be changed to see which glazing product will help lower the EUI. By uploading our models to Cove.tool, ARG sees the impact of our design decisions during all phases of design.

In Cove.tool, we were able to upload an early-stage model of our addition and drop it into the site next to the exisitng building that we are keeping. Cove.tool’s simulations were able to use daylighting, climate, and energy code minimums to generate our proposed EUI of 64.64 for the new addition.

Both tools improve our ability to quantify the carbon impact of projects early in the design process and help fine-tune specific design interventions to meet project sustainability goals. As a firm rooted in preserving special places, we implement these sustainable design strategies to augment our ability to help preserve this planet we all call home.