Katie Horak

Principal

When Elizabeth Sewall Schellenberg dreamt of a small chapel on a bluff overlooking the Pacific Ocean on the Palos Verdes Peninsula, she could never have anticipated that 100 years later, the bluff would fail and the chapel would begin to slide toward the sea.

In the late 1920s, Schellenberg, who was a member of the Swedenborgian church, envisioned a place of exquisite beauty where wayfarers could stop, rest, and give thanks to God. It would take more than twenty years for her dream to come to fruition, ultimately by the hand of Frank Lloyd Wright, Jr.

Wayfarers Chapel Interior, looking southwest, 1951. Julius Shulman, photographer, © J. Paul Getty Trust. Getty Research Institute, Los Angeles (2004.R.10).

For Wright, who had training both as a landscape architect and architect, the commission was the perfect challenge. His vision of a “tree chapel” aligned with the Swedenborgian emphasis on harmony between God’s natural world and the inner world of mind and spirit. The cornerstone was laid in 1949 and the chapel was completed in 1951, with the belltower, colonnade, annex building, and designed landscape completed a few years later.

Wayfarers Chapel, looking south, 1954. Julius Shulman, photographer, © J. Paul Getty Trust. Getty Research Institute, Los Angeles (2004.R.10).

Wayfarers Chapel is Wright’s masterpiece. It was recognized for its national importance through its designation as a National Historic Landmark in December 2023. The application, prepared by ARG, emphasized the chapel’s status as a seminal work of a noted architect and an important example of organic ecclesiastical architecture. In addition, the chapel holds a place in the hearts of the countless individuals who have experienced major life events there – weddings, funerals of loved ones, christenings – as well as those who have enjoyed more quotidian moments of meditation and reflection within its walls of glass and redwood.

So when Wayfarers leadership announced in February 2024 that the land was moving beneath the chapel and they were going to be forced to close, it was a devastating shock felt by many.

The Portuguese Bend Landslide Complex was originally identified in 1956, although at that time its movement was slow, just a few inches per year. In 2023, the landslide began to move at an unprecedented and surprising rate, and the first signs of a looming disaster were seen in shattered panes of glass at Wayfarers Chapel – first one, then another. By early 2024, geotechnical experts monitoring the landslide estimated that the earth was moving at a rate of roughly six to nine inches per week.

Broken glass due to earth movement.

Chapel leadership was left with the impossible question of what to do with the chapel while the earth moved beneath it. Other buildings on the Wayfarers site were deemed unsafe and red-tagged by the City, underground utilities were destroyed, and signs of the earth buckling and separating were increasingly seen in concrete pathways, the parking lot, and in the stone and concrete floor of the chapel itself. It became clear that the chapel would soon be destroyed as well if leadership did not act quickly.

Evidence of earth movement in concrete cracking/buckling.

It was important to Wayfarers leadership that the building retain its National Historic Landmark status, if possible, and consultation with the National Park Service and other historic preservation experts provided hope that the building could be moved offsite and reconstructed using its original materials without compromising its historic designation. The ARG team had prepared a Historic Structures Report for Wayfarers Chapel a decade prior, and with this existing knowledge of the building and an extensive research file of original Wright drawings and historic photographs of the complex under construction, the team was able to mobilize immediately and begin the process of planning for the deconstruction of the chapel.

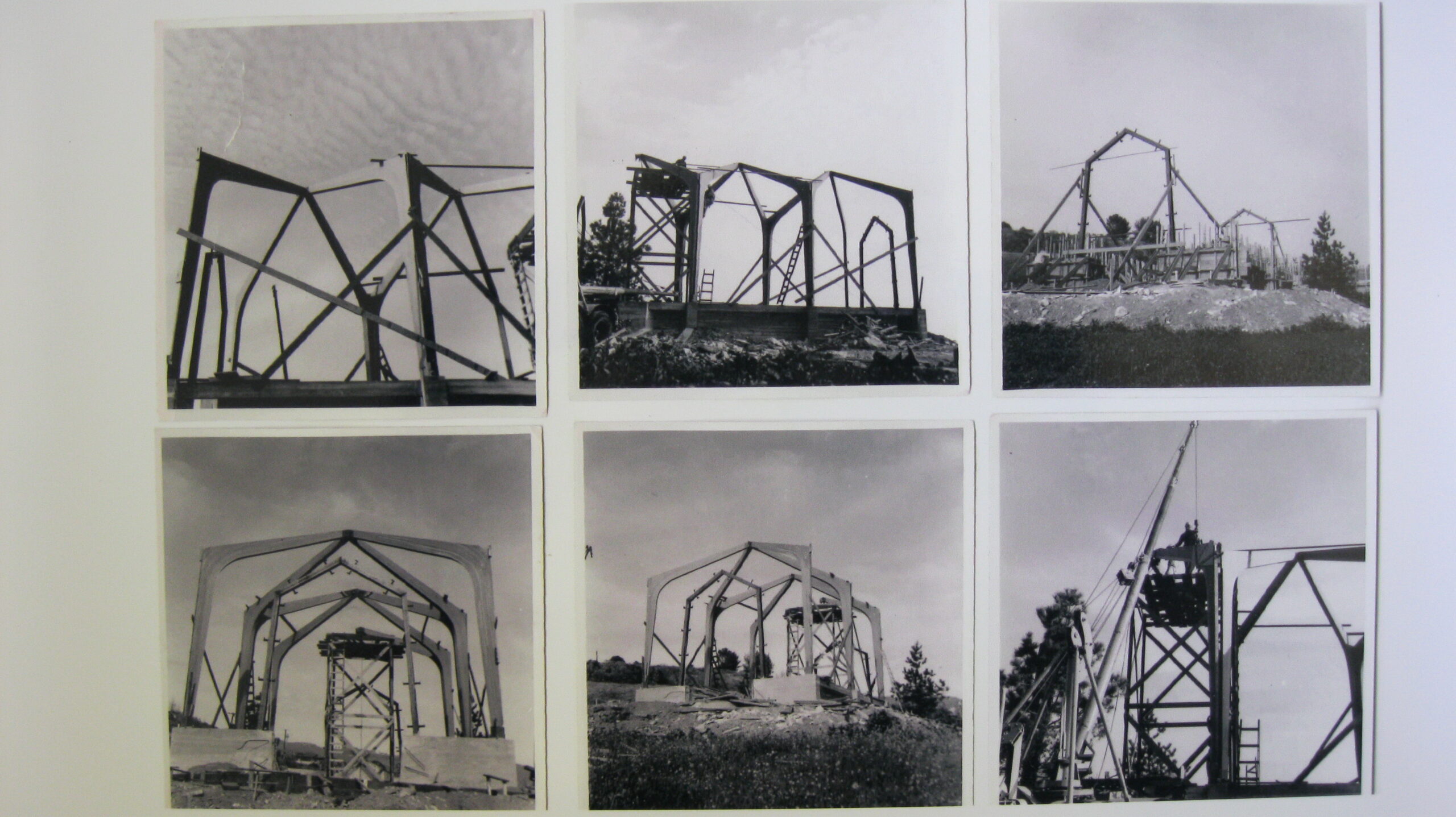

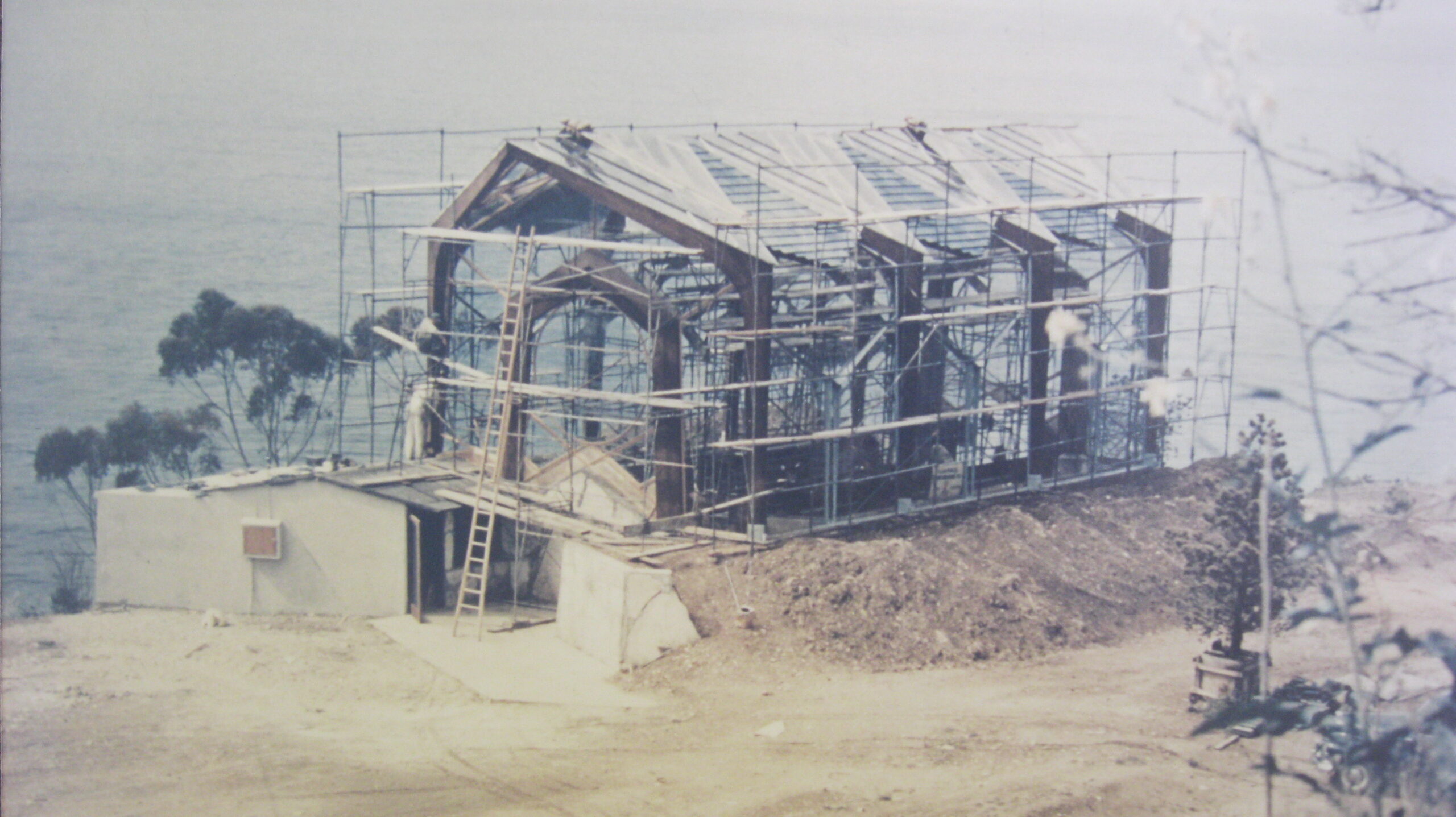

Wayfarers Chapel under construction, circa 1950. Courtesy of Wayfarers Chapel.

Wayfarers Chapel is constructed of old growth redwood glulam (glued laminated timber) bents, steel, and glass, rising from Palos Verdes stone berm walls. The chancel area and floors consist of Palos Verdes stone and concrete. Due to the nature of its construction, it was not possible to pick the building up in its entirety and move it off site. Rather, it would have to be taken apart much in the way it was constructed: methodically, piece by piece.

ARG’s first task was to create a drawing set that would guide the work of the contractor team in their disassembly of the chapel. These drawings detailed the sequence of disassembly, the way each piece should be documented and handled, and recommendations for safe storage. Working with a team that included construction manager Megan Turner from S. L. Leonard, contractors from K. C. Restoration and Tim Greenleaf Engineering (TGE), and structural engineers from TYLin, International, the disassembly commenced on May 14, 2024.

The sequence of disassembly included removal of glass first, which was actively breaking and falling on site, creating an unsafe condition for workers. Most of the glass had been replaced over time and was not original, although small samples were kept to inform future reconstruction. Clearing away some of the vegetation, including removal of a few of the redwood trees that envelop the chapel, was also a necessary first step in providing access to the structure. Loose items, such as original doors and window sashes, were carefully removed and tagged with numbers that correspond with a drawing set to ensure they can be put back in the same configuration. Original celadon blue roof tiles were removed from the chapel and colonnade and placed in crates for future reuse.

Left: Documenting loose items such as window sash for removal.

Right: Crating original blue celadon roof tiles for reuse.

Once these items were removed, the team could commence with the more challenging process of disassembling the building’s structure of redwood and steel. Over the course of just a few weeks, the intricate network of steel that held the chapel’s glass walls and skylights in place was removed as carefully as possible, leaving only the glulam bents. In anticipation of the removal of the bents, the team at K. C. Restoration designed and constructed custom cradles onto which the bents would be placed once removed from their brackets. Site conditions did not allow for the safe use of scaffolding or heavy equipment like cranes, so all the work had to be done using small lifts and telehandlers.

Left: Using lifts to access skylights for removal and salvage.

Right: Cracks in the concrete at the chapel interior showing continued expansion.

While the team worked, the earth continued to move. With each day, cracks had widened, buckling concrete worsened, and tension continued to build in the bents, which were being increasingly pulled by the earth onto which they were anchored. These changing conditions required that the team be nimble, constantly evaluating and reevaluating the disassembly sequence.

The sixteen redwood bents were removed over the course of one week in mid-June. The plan was to carefully lift each bent, one at a time, using a telehandler, while the others were tethered to the surrounding redwood trees for stability. Relying on their knowledge of boat building, the contractors used sailing knots and rigged each bent at the perfect “pick point,” or center of gravity, so that its weight was equally distributed for safe transport to the cradles.

Lifting the first glulam bent from its base bracket for transport to the cradle.

Carefully lowering the first glulam bent onto its cradle.

The team watched nervously as the first bent was removed: first, the unfastening of bolts at steel brackets at the base and at the roof peak, where the bents were held together. Then the first bent was then pulled up out of its base bracket and appeared to float across the site as the telehandler carried it to its cradle, onto which it softly rested. This process was repeated 15 more times, with four bents on each cradle, in perfect choreography. When the last bent was placed on its cradle, overwhelming feelings of relief, sadness, and joy could be felt throughout the team, and then quiet, with all of the equipment turned off and the group enjoying a well-deserved break, looking out over the Pacific Ocean.

Getting ready to remove the last glulam bent.

Top: All 16 bents on their cradles.

Bottom: The team taking a break after the last bent had been placed on its cradle.

The hard work continues, and it is the hopeful work of finding a new site on which Wayfarers Chapel can rise again. The component parts of the chapel will be safely stored on solid ground until a suitable new location for reconstruction is identified. Meanwhile, the Palos Verdes stone on the original Wayfarers site will be salvaged for future reuse, so that when the structure is erected again, it will rise from a foundation of native stone, as originally designed by Wright.

Working on the Wayfarers Chapel disassembly has been an experience unlike any other for the ARG team. It has been at once devastating to watch this place we love so deeply come apart due to the forces of nature, thrilling to get caught up in the adrenaline of working against the clock with such a talented and committed team, and hopeful to stay focused on a future chapel, reconstructed with original materials per Wright’s drawings.

It’s been humbling to be trusted with this process by Wayfarers Chapel leadership, for whom the chapel is so much more than stone, steel, redwood, and glass. From the beginning, the disassembly team has kept their eyes on the future chapel: a place that would be recognizable to Schellenberg and those in the Swedenborgian congregation who participated in its original construction, and that will encapsulate the intangible beauty and spirit of the natural environment, this time on solid ground.

Members of the disassembly team on site.